Power meter accuracy and calibration 101

There are many things that can affect the accuracy^ of power meters, but let's talk about one of the most important, i.e. the person using the power meter.

Most common on-bike power meters in use today (e.g. SRM, Powertap and Quarq, and more recent offerings from Power2Max and others) require a user to do three things for accurate data:

- Pair the handlebar computer with the right power meter – this might be via a wireless protocol such as ANT+, or by simply plugging the two together via their wiring harness

- Check the torque zero before and occasionally during a ride (torque zero or "zero-offset" as referred to by SRM are interchangeable terms in this context)

- Check / validate the correct slope calibration of the power meter is being used

However I want to elaborate on #2 (torque zero / zero-offset) & #3 (slope calibration) via an analogy – the ubiquitous bathroom scales that many have a love/hate relationship with.

To demonstrate the difference between "zero-offset" and "slope calibration" and their importance, I'm going to share with you a simple experiment - checking the accuracy of an old set of bathroom scales I have. They are the old fashion type with an “analogue” display that rotates around when you hop onto the scales.

Here’s a pic of the scale's reading before I place a known weight on the scales. The lower scale is kilograms (kg) and the upper scale is stone and pounds. I'll stick with kg for now.

We can see they are reading +4kg when there is nothing on the scales. Clearly the “zero-offset” is wrong. So if I placed a known mass on the scales, I should expect the scales will read 4kg too high.

So, let’s place an accurately known weight on the scales. I just happen to have an accurately known weight of 31.210kg. Rounding to 31.2kg will do for this example. This is what we see:

That’s reading 34kg. But hang on, shouldn't we expect the scale to read 35.2kg = 31.2kg (actual weight) + 4kg (the "zero-offset")?

Well yes, we should, but it isn’t. Hang on to that snippet - we'll get back to it shortly.

The scales have a small “zero control” knob, which I can turn so the scales are reading zero when I am not standing on them. All we are doing is validating that, when no weight is on the scale, it displays a zero value. OK, so let's correctly set the “zero-offset” on the scales:

and now put the weight back on the scales again:

Now it says 30kg. Hmmm, so even though the “zero-offset” setting is correct, my scales are under reading the actual weight by 1.2kg or about 4%.

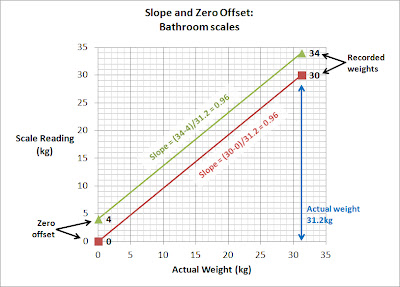

Let’s plot those readings.

Let’s plot those readings.

There are four readings. The two for when the scale’s zero-offset was +4kg (the green triangles and line), and the two when the scale’s zero-offset was 0kg (the red squares and line).

The horizontal axis is the actual weight placed on the scales, which in this case is either 0kg or 31.2kg. The vertical axis is the reading provided by the scales.

So now we can visualise two things:

- the “zero-offset”, which shows us how much the scales read when there is no weight applied, and

- the “slope”, of the scale – in other words, how much weight the scales report increasing by for every kg of actual weight placed on the scale.

[Reported weight - Zero-offset weight] / Actual weight

In this case for both sets of readings, the slope is 0.96.

Hence, if I stood on these scales, and the zero-offset had been set correctly to 0kg, and the scales read 83kg, I would actually weigh 83 / 0.96 = 86.5kg.

So even though the “zero-offset” has been correctly set to zero, this does not mean the scales have been calibrated, nor that they are accurate. All we know after performing a "zero-offset" is they will read correctly when there is no weight on the scale - but that does not ensure accuracy when we step on the scales.

In order for the scales to be accurate, we need to know not only the zero-offset is correct but also their slope is correct. In this case the slope of the scales is wrong, and hence the weight reading will be wrong unless I apply the correct slope to the "raw" data.

The exact same principle applies to bicycle power meters. Instead of weight on a scale, most power meters measure the torque (twisting force) applied to a bicycle component (using special gauges). The most common meters measure the forces at the crank spider or at the rear hub but forces can also be measured at the pedal or cleat, the crank arms, or the rear cog (or even the chain). Besides measuring the torque applied to the component, all that is required to determine power is the the rotational velocity of the component (revolutions per unit time).

So to complete the analogy:

- The zero-offset (or torque zero) of a power meter is the torque reading when there is no force being applied to the crank (or hub) and is analogous to the bathroom scale's reading with no weight on them. Various power meters report in different units.

- The slope of a power meter is a value indicating the increase in the reported torque readings per unit of actual torque applied to the crank (or hub) and is analogous to knowing how much the bathroom scale's reading changes for each kg of actual weight we put on them.

Checking and/or re-setting the torque zero (zero-offset) of your power meter before and occasionally during a ride is a necessary and sound practice,

however

unless you also know the correct slope of your power meter is being used, then the data may still be inaccurate.

This auto-zero / correction feature may or may not be a good thing depending on how it has been implemented. In my opinion, I consider knowing how and when such changes occur to be useful and valuable information when evaluating the possible errors in reported power data.

There are also some things that can affect the slope of your meter between when it left the factory to when it is finally installed on your bike, so I encourage you to have the slope validated while the meter is actually on your bike. Slope checks are best done at a 6-12 monthly intervals, or whenever you make changes to the crank's set up (such as changing cranks arms or chainrings).

Some power meters have far more stable slopes than others. It’s not a difficult thing to check yourself, but I’ll look at providing an example of that process in another post.

In the meantime, the good folk at Quarq have provided a video to demonstrate the slope checking process for their power meter. It's a similar process for other meters but the means to obtain the torque numbers and calculate the slope will vary.

As a final comment - it's possible to post-hoc correct power data that has had an incorrect slope applied but an incorrect zero-offset/torque zero can be a lot more difficult (if not impossible) to correct, and especially so if that zero-offset has been drifting. For SRM users, applying a slope or zero-offset correction is pretty trivial to perform using SRMwin software.

* The confusion hasn't been helped when one of the major manufacturers of bicycle computer recording devices (i.e. Garmin) use the terminology "calibration" for their device, when the specific function they refer to as "calibration" it is not a true calibration. If you use a Garmin computer, and "calibrate", I suggest in your own mind to replace the Garmin word "calibration" with the words "torque zero".

^ When using a power meter, we want to ensure that the data is as accurate and precise as possible. We do this for many reasons, in particular so we can make valid comparisons of performance changes over time (keeping in mind that the gains at high levels of relative fitness are only a handful of percent and people may not use the same power meter their entire lives). There are also many performance analyses that require accurate and precise data to make valid but important choices about performance matters, e.g. the testing of aerodynamics, or tyre rolling resistance. Anyway, I’m not going to labour why accuracy and/or precision is important, that’s for another discussion.

5 comments:

Very nice explanation. I've tried to make these same distinctions but from now on I'm just pointing people to here.

Loving your work Alex

Installed a Stages crank power meter 4wks ago and it seemed to work perfectly until the crank came off (complete mystery) and since refitting the readings have gone awol despite recalibrating the new Garmin 500 - should I presume the meter has been damaged ?

Since you cannot calibrate a Stages power meter, I suggest talking to the Stages people for troubleshooting help.

Great explanation. Agree with you on calibration, I will now be calibrating every 6-12months.

Alex, have you calibrated Quarq’s?

I run 3 Quarqs on different bikes and felt recently that one of my road bikes using an ELSA R was reading lower than my other road bike which has a new DZero. I got a certified 20kg weight and calibrated all three units. The ELSA R was 5% low, the DZero was 2% low, and the Quarq SRAM Red on my TT bike was spot on. Big differences!!! When I reported this to Quarq customer service they recommended against field calibration, stating it was no longer necessary (post Cinqo’s) and claimed the factory slope was better. Thing is, I know they measure inconsistently using the factory slopes. So I’ll stick with my field calibration slopes.

Hey, do you know the units of the slope for Quarqs? I believe the units of the SRM slope is Hz/Nm, but that doesn’t seem to make sense for my Quarq slopes.

Post a Comment